Complexities in Manufacturing Processes

The production of viral vectors presents a multitude of intricate challenges that necessitate attention and sophisticated solutions. A primary obstacle lies in refining the design of vectors to guarantee both safety and efficacy. Each vector must undergo meticulous engineering to execute its function without eliciting detrimental immune responses.

Balancing Yield and Safety

Another pivotal concern involves minimizing immunogenicity, where the immune system reacts adversely to the vector, while simultaneously maximizing its yield. Attaining this delicate balance is indispensable for effective therapeutic applications. Techniques such as advanced genetic engineering and leveraging cutting-edge biotechnologies can aid in refining vector attributes and enhancing overall safety profiles.

Overcoming Scalability and Quality Assurance Hurdles

Scalability poses a significant challenge, particularly due to the intricate concentration and purification processes required for commercial-scale viral vector production. Addressing these hurdles necessitates the implementation of robust, scalable production systems and the enhancement of purification methodologies. Continuous innovation in production processes is crucial to meet stringent quality standards without compromising on scale.

DNA Synthesis

DNA Synthesis Vector Selection

Vector Selection Molecular Biology

Molecular Biology Oligo Synthesis

Oligo Synthesis RNA Synthesis

RNA Synthesis Variant Libraries

Variant Libraries Genome KO Library

Genome KO Library Oligo Pools

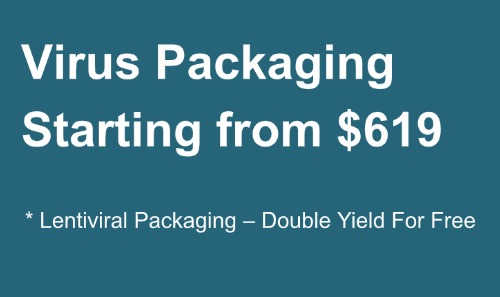

Oligo Pools Virus Packaging

Virus Packaging Gene Editing

Gene Editing Protein Expression

Protein Expression Antibody Services

Antibody Services Peptide Services

Peptide Services DNA Data Storage

DNA Data Storage Standard Oligo

Standard Oligo Standard Genome KO Libraries

Standard Genome KO Libraries Standard Genome Editing Plasmid

Standard Genome Editing Plasmid ProXpress

ProXpress Protein Products

Protein Products