Collagen, a vital protein found abundantly in various tissues, has traditionally been extracted from animal sources. This method, while established, faces challenges such as the risk of infectious diseases and inconsistent quality. As global collagen demand escalates, we’re reaching the limits of traditional extraction methods.

A New Strategy for Collagen Sourcing

To circumvent the drawbacks of animal-derived collagen, a shift towards synthetic biomanufacturing has emerged. Utilizing the prowess of genetic engineering, scientists now synthesize recombinant collagen and peptides in diverse host cells, including plants, insects, bacteria, and yeast. This bio-manufactured collagen boasts higher biocompatibility, superior water solubility, and reduced immunogenicity, marking a paradigm shift in industries ranging from pharmaceuticals to food and energy.

Recombinant Collagen Commercialization: A Catalyst for R&D

Advancements in DNA sequencing, synthesis, and editing have revolutionized collagen production. With precise control over collagen DNA synthesis, we achieve unparalleled consistency and reliability, propelling R&D forward.

Human collagen, known for its diversity and structural complexity, comprises 28 identified types. Of these, types I, II, III, VI, and XIII are garnering significant research attention. The spotlight on recombinant collagen in research, industry, and capital markets underscores the critical role of synthetic biology in R&D innovation.

Applications Across Industries

Biopharmaceuticals: Use in biological dressings for skin and oral repair, drug carriers, and medical aesthetic injectables.

Functional Skin Care: Innovative products focusing on whitening, moisturizing, and anti-aging.

Food Industry: Hydrolyzed collagen in chewable tablets and protein powders.

Enhancing the Recombinant Collagen Production Process

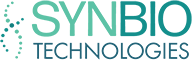

The journey from gene to collagen involves meticulous steps:

- Gene Design and Synthesis: Target collagen genes are cloned and integrated into appropriate vectors.

- Expression System Construction: These vectors are introduced into host cells like E. coli or yeast for protein expression.

- Fermentation Optimization: Critical factors like nutrient supply, pH, and temperature are finely tuned.

- Protein Purification: A series of purification steps isolate and refine the collagen protein.

- Protein Characterization: Techniques like SDS-PAGE and mass spectrometry confirm the protein’s identity and activity.

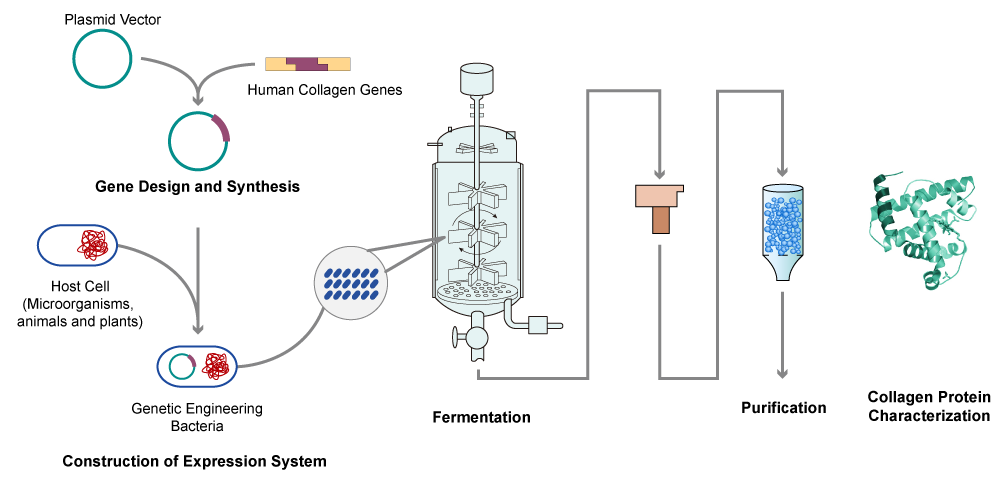

Synbio Technologies: Pioneering Synthetic Biology Solutions

At Synbio Technologies, our expertise in synthetic biology and biomanufacturing sets us apart. We provide comprehensive solutions in recombinant collagen production, ranging from custom genetic components to optimized cell factories. Our collaborations and innovations in this field have positioned us at the forefront of biomanufacturing.

Looking Ahead: The Future of Collagen Production

The trajectory of recombinant collagen is one of continual innovation and expansion. As we look to the future, the potential for new applications, technological breakthroughs, and the sustainable meeting of global demands is immense. Synbio Technologies remains committed to leading the charge in this exciting and transformative field.

References

Yuanyuan ZHANG, Yan ZENG, Qinhong WANG. Advances in synthetic biomanufacturing[J]. Synthetic Biology Journal, 2021, 2(2): 145-160.

Sorushanova A, Delgado LM, Wu Z, Shologu N, Kshirsagar A, Raghunath R, Mullen AM, Bayon Y, Pandit A, Raghunath M, Zeugolis DI. The Collagen Suprafamily: From Biosynthesis to Advanced Biomaterial Development. Adv Mater. 2019 Jan;31(1):e1801651.

Fu R, Fan D, Yang W, Chen L, Qu C, Yang S, Xu L. [Industrial development and biomedical application prospect of recombinant collagen]. Sheng Wu Gong Cheng Xue Bao. 2022 Sep 25;38(9):3228-3242. Chinese.

Zhang YP, Sun J, Ma Y. Biomanufacturing: history and perspective. J Ind Microbiol Biotechnol. 2017 May;44(4-5):773-784.